Natural dyeing: what are the advantages of bacterial pigments?

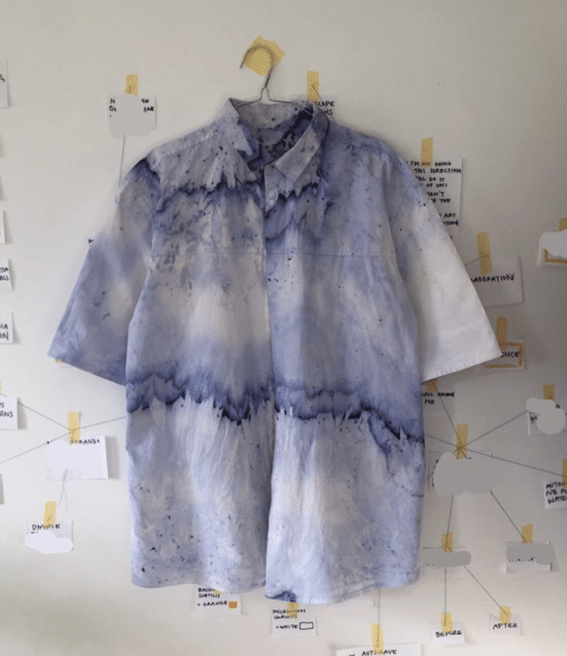

“Designing with nature, not against it, requires alternative practices and new tools”.. British designer and scientist Charlotte Werth has come up with a new approach to natural dyeing: “Moving Pigments”. This revolutionary project aims to extend and automate the process of co-designing textile patterns with pigment-producing bacteria. The goal ? To magnify a reality usually hidden from our eyes, revealing the incredible beauty of this parallel microscopic world.

The dyeing method using bacteries pigment producers is to substitute the chemicals used in the traditional dyeing process, which have an environmental impact. In fact, mass production and consumption have led to extensive use of petrochemical dyes. These often have disastrous repercussions on ecosystems, polluting waterways and landscapes. Bacterial dyes, on the other hand, offer a number of ecological advantages, including much lower water consumption and the absence of harmful chemicals. Integrating this method into the fashion and textile sector would therefore be necessary to offer an ecological alternative.

What is bacterial dyeing?

“Bacterial dyeing is a beautiful and unique dyeing method, creating colour gradations and lines that cannot easily be imitated”., explains Charlotte Werth to Future Materials Bank (a materials archive that supports and promotes the transition to ecologically conscious art and design practices). However, microbes thrive in slightly unexpected ways and are part of the design process. “By placing living organisms at the heart of a collaborative production process, the result can be explicitly designed but never exactly predicted”., she says. Co-designing and co-producing with micro-organisms means understanding how they grow and applying this to the creation of designs.

“Challenging the established separation between human and non-human species can create significant innovation”,

Charlotte Werth

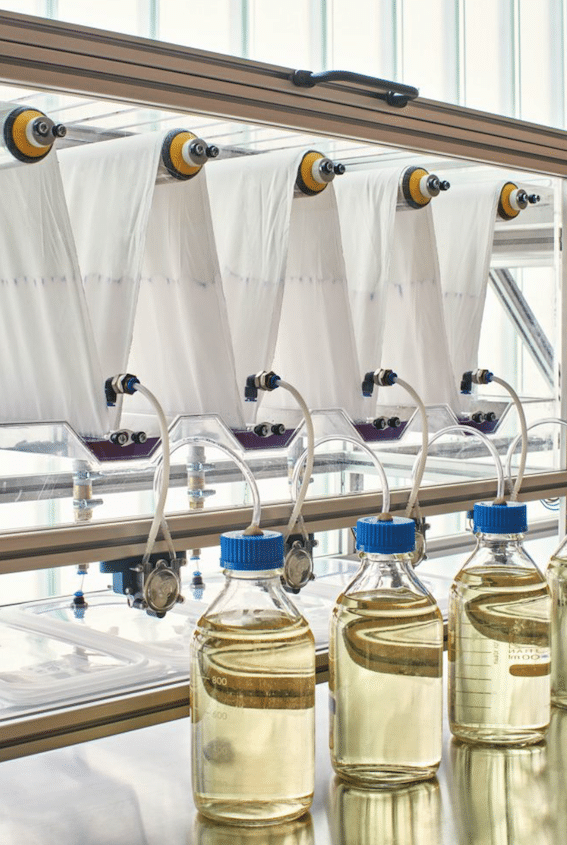

The machine developed as part of this work is designed to experiment and explore the bacterial dyeing process through automation.

Photos: Tom Mannion and Suzie McMurtry for Future Materials Bank.